Ion Chromatography Services

|

| Dendritic growth formation on the surface of an assembly. Surface contaminants can facilitate metallic growth (dendrites) in the presence of electric current, moisture, and/or heat. |

on Chromatography analysis (IC) is an essential tool for both failure analysis and process validation. PSI uses IC to investigate surface contamination and measure ionic cleanliness of finished assemblies. Common ionic contaminants, such as flux residues, fingerprints, debris, or electroplating solutions can be detrimental to the yield and reliability of electronic circuit assemblies. Moisture, electricity, and heat interact with these ions to cause dendritic metal migration, and eventually shorts and/or corrosion. Cleanliness testing using ion chromatography ensures your boards are getting a clean start.

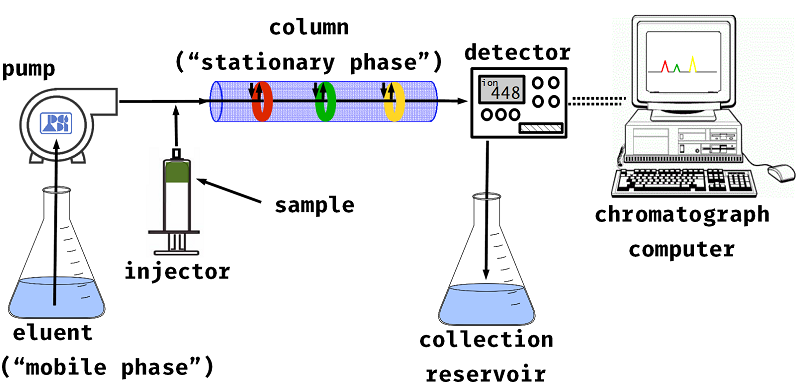

How Ion Chromatography works

An extracted sample (the "analyte") is injected into a liquid medium (the eluent, or the "mobile phase"), which is pumped through a column containing an ion exchange material (the "stationary phase.") As the analyte ions pass through the column, their affinity for the stationary phase will exceed their affinity for the mobile phase, and they will react with the stationary phase medium. This chemical exchange happens at different rates for each type of ion in the analyte. A detector then "reads" these changes in the solution chemistry, using UV absorption, electrochemical, or other methods. These data are sent by the detector to an attached workstation, which interprets the signals and graphs the results. Each graph peak identifies an ion from the original sample.

Ionic Cleanliness Testing Methodology

Analysis normally follows IPC-TM-650 test method 2.3.28, which defines extraction and analysis procedures for testing board anionic contamination levels. This extraction method is designed for cleanliness testing for process validation purposes. However, for identification of foreign materials, customers will typically extract or collect material sample themselves and send them to us for analysis. In such cases the scope of analysis becomes identification rather than quantification. In either application, only trace amounts are needed for accurate analysis.

Process Sciences uses a modular Dionex IC system made by Thermo Scientific. Our system features an RG-40 reagent-free eluent system, and two detectors, models Ultimate 3000 (UV absorption) and ED-40 (electrochemical.) Our system can be calibrated for both common anions such as fluorides, chlorides, bromides, nitrates, sulphates, and phosphates, and cations like sodium, potassium, calcium, silver, aluminum, etc.

ion chromatography services | ionic cleanliness testing