COPLANARITY SERVICES | LEAD STRAIGHTENING

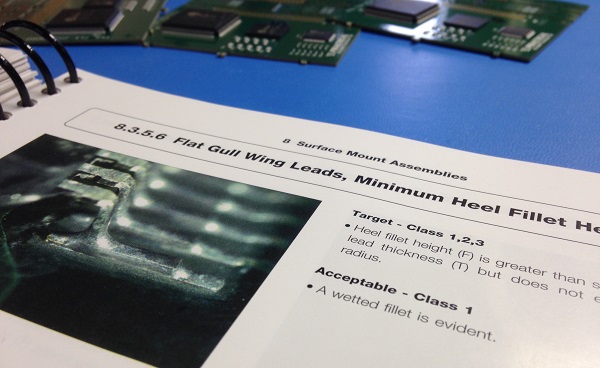

he goal of coplanarity repair is not to restore to "like new" condition, but to prepare components for successful SMT placement. IPC publication IPC-A-610 §8.3.5 outlines a standard of acceptability for soldering of flat gull wing leads, including tolerances for X, Y, and Z (height) axis alignment. It should be noted that IPC standards do not governmaterial quality per se, but the final solder quality of finished assemblies. Nevertheless, IPC is instructive to any repair process whose ultimate goal is to ensure the best chance of successful placement. On the X axis, each lead must be situated substantially over the pad, such that the side overhang is not greater than 50% (Class 1,2) or 25% (Class 3) of the lead width. Toe overhang is allowed under Class 1, 2 & 3, provided it does not violate minimum electrical clearance. Acceptable Z axis variations are not specified by IPC, except as it relates to heel fillet height. Priority attention is given at PSI to the X and Z axes, as variation there is most likely to produce opens or bridged circuits.

The Repair Process

Manipulation of leads is accomplished using special tweezers and flat-blade tool adapted for the purpose, on a coplanarity mirror, and under 10x to 25x magnification. On the Z axis, leads are straightened to coplanarity to a spec of +0.004/-.0.0 inches. X axis (side overhang) corrections are performed under magnification to achieve uniform spacing and perpendicular angles to the body. The Y axis variation (toe overhang) is generally not emphasized, as IPC guidelines allow for substantial variation there. Typically there is some variation in alignment of toes, as shown in the image above. Repaired devices will be ready for SMT processes, but will still show evidence of repair. Therefore customers looking for "mint" components must explore other sourcing options than coplanarity restoration.

"Recoin" vs "Repair"

The term "recoining" refers to the process of shaping, or "lead forming," using specialized equipment and custom tooling. Unlike lead straightening, which is a means of refurbishing damaged parts, recoining is typically a packaging or OEM process for re-shaping new part leads.

IPC Standards guide our repair process. PSI's goal is to prepare components for successful SMT placement. Quality is guaranteed. PSI conducts 100% visual inspection on all coplanarity orders.

coplanarity services, lead straightening