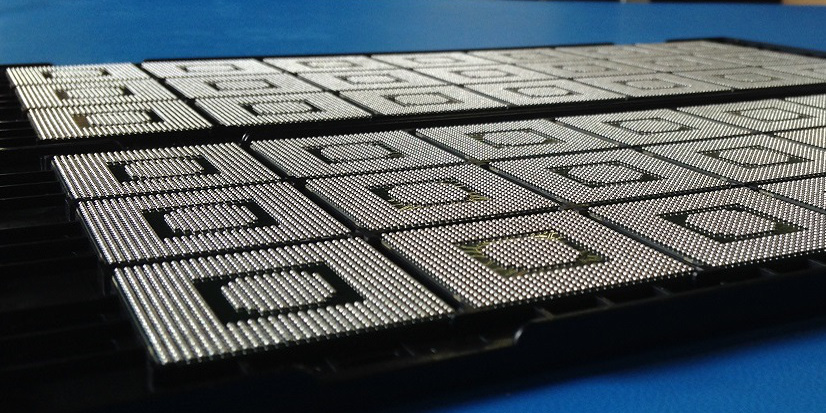

BGA Alloy Conversion

PSI has over 25 years experience reballing BGA devices of every size, pitch, and package style. Our facilities are ESD safe and precautions are taken to ensure proper handling and care. Before rework, components are baked to remove moisture. During sphere attach, thermal cycles are carefully monitored with regard to alloy and package characteristics. PSI inspects 100% of parts before dry-packing your order for return shipment. At PSI, your parts are in good hands.

Conversion to Sn/Pb

For military, aerospace, and other high reliability or mission critical applications, tin lead eutectic solder (Sn63-Pb37) offers superior mechanical strength and higher yields than Pb-free alternatives. However many OEMs no longer offer a Sn/Pb option on the packages you need. PSI can help. We are the go-to partner to many contract manufacturers and OEMs for Sn/Pb alloy conversion. Our proprietary processes for cleaning, pad prep, and sphere attach are reliable, scalable, and efficient. Your parts will arrive clean, safe, baked and dry-packed, and marked or dotted per your requirements.

Conversion to Pb-free

RoHS requirements have changed the landscape of electronics manufacturing. Whether you are holding inventory of older Sn/Pb parts, or facing supply chain constraints for the Pb-free version you need, PSI can help. We can reball with SAC305 or Sn96.5-Ag3.5 spheres, and return your parts clean, baked and dry-packed. Pb-free parts are typically marked with a green dot by convention, but we can also mark with UV marker, or not at all.